Description

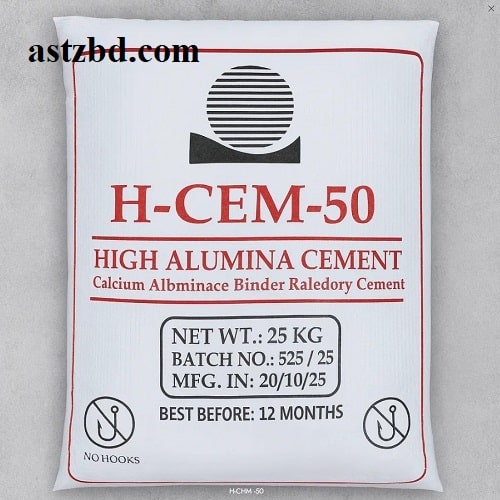

HI-CEM-50 (also known as H-CEM-50) is a high alumina refractory cement (calcium aluminate cement) manufactured by Horizon Refractories Private Limited in Ahmedabad, Gujarat, India. It is a conventional refractory binder with approximately 50% Al₂O₃ (alumina) content, designed for high-temperature applications where rapid setting, excellent binding properties, and resistance to thermal shock and chemical corrosion are required

Key Specifications

| Property | Value |

|---|---|

| Al₂O₃ Content | 50% ± 2% |

| CaO Content | 35–40% |

| Initial Setting Time | 60–180 minutes |

| Final Setting Time | ≤ 5 hours |

| Compressive Strength (24 hrs) | ≥ 35 MPa |

| Max Service Temperature | 1400°C (3272°F) |

| Refractoriness (PCE) | ≥ 32 |

| Specific Gravity | 2.9–3.1 g/cm³ |

| Fineness (Blaine) | ≥ 3200 cm²/g |

Performance Advantages

- Rapid Strength Gain: 70% strength in 24 hours — ideal for emergency repairs

- Thermal Stability: Perfect for kiln patching, boiler linings, and foundry molds

- Chemical Durability: Resists sulfates, chlorides, and seawater — certified for coastal & marine RCC

- User-Friendly: No Hooks™ design ensures safe handling & clean pouring

- Cost-Effective: 30% lower cost than 70% alumina grades, same Japanese precision

Applications

- Rapid runway & highway repairs

- Precast refractory bricks and blocks

- Sulfate-resistant foundations (piers, canals, dams)

- Medium-temperature furnace linings (≤ 1400°C)

- Gunning mixes and patching compounds

- Marine & offshore concrete structures

- Primary binder for manufacturing refractory castables, mortars, and monolithics

- Used in furnaces, kilns, boilers, incinerators, and foundry linings

- Steel plants (as flux or in slag control)

- Cement kilns and petrochemical industries

- Emergency repairs requiring quick setting at high temperatures

- Mixed with refractory aggregates (e.g., bauxite, fireclay) to form heat-resistant concrete

Reviews

There are no reviews yet.