Description

1. Applicable Standards:

- GB/T 2611-2007: “General Technical Requirements for Testing Machines”

- JB/T 7406.1-1994: “Testing Machine Terminology – Material Testing Machines”

- GB/T 3808-2010: “Inspection of Pendulum Impact Testing Machines”

- GB/T 229-2007: “Charpy Pendulum Impact Test Method for Metallic Materials”

- JJG 145-2007: “Pendulum Impact Testing Machines”

- ISO 148:1998: “Metallic Materials – Charpy Pendulum Impact Test”

- ASTM E23-07a: “Standard Test Methods for Notched Bar Impact Testing of Metallic Materials”

- GB/T 18658-2002: “Standard Charpy V-Notch Specimen for the Inspection of Pendulum Impact Testing Machines”

- JB/T 6147-2007: “Technical Requirements for Packaging, Marking, Storage, and Transportation of Testing Machines”

2. Main Technical Parameters

| Item | JBW-450C |

| Maximum Impact Energy (C) | 450 |

| Effective Usage Range | 10% – 90% FS |

| Pre-Raised Pendulum Angle | 150° |

| Distance from Pendulum Axis to Impact Center | 750 mm |

| Impact Speed | 5.24 m/s |

| Anvil Span | 40 mm |

| Anvil Fillet Radius | R1 – 1.5 mm |

| Anvil Inclination Angle | 11° ± 1° |

| Impact Blade Angle | 30° ± 1° |

| Impact Blade Curvature Radius (2 mm Blade) | 2 mm – 2.5 mm |

| Impact Blade (8 mm Blade) | 8 mm ± 0.05 mm |

| Impact Blade Shoulder Fillet Radius (8 mm) | 0.1 mm – 1 mm |

| Impact Blade Width (8 mm Blade) | 4 mm ± 0.05 mm |

| Overall Impact Blade Width | 10 mm – 18 mm |

| Impact Knife (Blade) Thickness | 16 mm |

| Specimen Size (mm) | 10×10×55; 10×7.5×55; 10×5×55; 10×2.5×55 |

Overall Machine Parameters

| Item | JBW-450C |

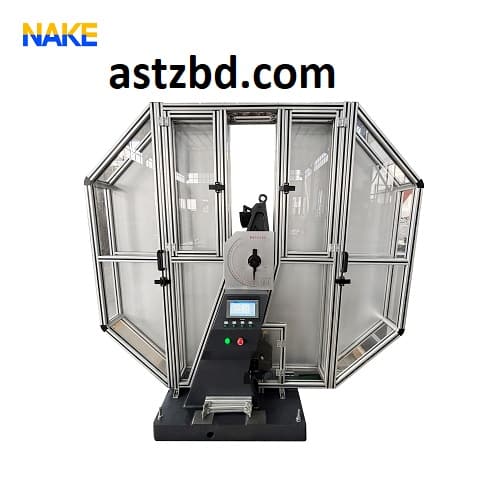

| Overall Dimensions | Main Unit: With acrylic protective cover, 2220 × 900 × 2220 (L×W×H) Electrical Cabinet: 960 × 620 × 830 (L×W×H) |

| Weight | Main Unit: Approximately 1500 kg Electrical Cabinet: Approximately 100 kg |

| Specimen Recovery Device | Automatically recovers the specimen after each test; safe, convenient, and reliable |

| Safety Protection Device | Main unit is equipped with a fully enclosed safety shield featuring an aluminum alloy frame and tempered glass |

| Door Interlock Power-Off | The safety system includes a door access switch to cut power when the door is open |

| Power Failure Protection | Reliable disc brake ensures the pendulum stops during a power outage |

| Expansion Capability | Reserved interface for robotic automatic specimen feeding; upgradeable to a fully automatic testing machine in the future |

| Motor Power | 1.5 kW |

| Power Supply | Three-phase five-wire system, 380 V ± 10%, 50 Hz |

| Operating Environment | Vibration-free, dust-free; Room temperature (15-25 °C); Humidity < 70% |

![CALIFORNIA BEARING RATIO TEST, California Bearing Ratio (CBR), Laboratory California Bearing Ratio Test Apparatus, LABORATORY CBR APPARATUS, California Bearing Ratio [CBR] Test Machines, California Bearing Ratio CBR Test Apparatus, california Bearing Ratio Apparatus, CBR testing machine, California Bearing Ratio, CBR Test Apparatus, Cbr Test Machine, Laboratory CBR Test Apparatus, CBR Machine, Soil Lab Test Machine, Electric Cbr Test Machine, Electrical CBR Test Machine, CBR Testing Machine](https://astzbd.com/wp-content/uploads/2023/06/lab-cbr-test-apparatus-500x500-1-300x300.jpg)

Reviews

There are no reviews yet.